GENMA大型龍門吊強在哪?_風聞

港口圈-港口圈官方账号-1小时前

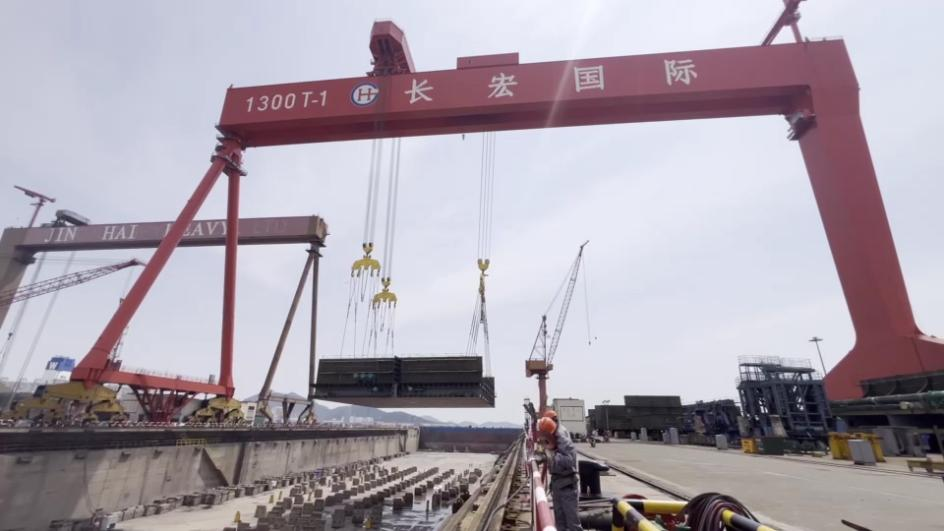

近日,由GENMA為客户提供的1300噸級×146米超大型雙主樑門式起重機(簡稱:龍門吊)成功完成多個噸位分段的起吊、移動、定位和翻轉試驗,順利通過上海特檢院、舟山特檢院型式試驗特檢驗收。整個試驗過程,設備運行平穩,定位精準,其出色的表現彰顯了GENMA在大型化、智能化起重解決方案上的技術優勢。

該龍門吊採用智能化控制系統,配備防搖擺裝置和即時監測功能,有效提升了設備吊裝精度和作業安全性,特別適用於船舶等大型結構件的總裝作業。在動力系統方面,設備應用了能量反饋技術,可將運行過程中的重力勢能轉化為電能循環利用,實現節能環保運行,有助於提高現場生產效率同時降低設備能耗。

此台設備是GENMA為該客户提供的首台龍門吊,另一台同規格設備目前已進入總裝階段,這兩台龍門吊均由南通潤邦重機有限公司生產製造。未來,GENMA將繼續以可靠的產品和定製化服務,為行業客户提更高效、更智能的物料起重搬運解決方案。

Recently, the 1300-ton × 146-meter Ultra-large double-girder gantry crane (abbreviated as gantry crane) provided by GENMA for its client successfully completed multiple hull blocks tests—including lifting, moving, positioning, and turning operations—and passed the type test acceptance inspection conducted by the Shanghai Special Equipment Inspection Institute (SAEI) and Zhoushan Special Equipment Inspection Institute (ZSEII). Throughout the testing process, the equipment operated smoothly and achieved precise positioning, demonstrating GENMA’s technological prowess in delivering large-scale, intelligent lifting solutions through its outstanding performance.

This gantry crane features an intelligent control system equipped with anti-sway technology and real-time monitoring, significantly enhancing lifting precision and operational safety. It is particularly suited for assembling large structural components like ships. The crane’s power system utilizes regenerative feedback technology, converting gravitational potential energy during operation into reusable electricity, enabling energy-efficient and eco-friendly performance while reducing operational costs.

As the first gantry crane GENMA delivered to this client, a second unit of the same specification is currently in final assembly. Both cranes were manufactured by Nantong Rainbow Heavy Machineries Co., Ltd. Moving forward, GENMA will continue to provide reliable products and customized services, delivering smarter, more efficient material handling solutions for industrial clients worldwide.